Galaxy Entertainment Group (GEG), one of Asia’s leading gaming and entertainment destinations, operates three flagship properties in Macau – on Cotai, Galaxy Macau™, one of the world’s largest integrated destination resorts, and the adjoining Broadway Macau™, a unique landmark entertainment and food street destination; and on the Peninsula, StarWorld Macau, an award-winning premium property.

Located in the heart of Cotai, Macau’s fast-growing hotel-casino area, Galaxy Macau is a fully integrated destination resort and the first and only resort to offer six world-class hotels in a single destination – The Ritz-Carlton’s all-suite hotel, The Ritz-Carlton, Macau; Banyan Tree Macau, Asia’s largest JW Marriott, the JW Marriott Hotel Macau; the first Japanese luxury hotel in Macau, Hotel Okura Macau, the award-winning Galaxy Hotel and the Broadway Hotel.

In total, Galaxy Macau offers close to 4,000 rooms, suites and villas, bringing guests a diverse range of lavish hospitality experiences. Its 75,000-square-meter Grand Resort Deck features the Skytop Adventure Rapids – the world’s longest Skytop aquatic adventure river ride at 575 meters – as well as the world’s largest Skytop Wave Pool and a pristine white sand beach.

Galaxy Macau is home to 120 food and beverage outlets including 13 Michelin-starred restaurants, offering the largest selection of authentic Pan-Asian and world-class dining destinations in Macau.

SUSTAINABLE AMBITION

GEG supports the Macau SAR Government’s vision of “Building a Low-Carbon Macao, Creating Green Living Together” and the company proactively promotes energy conservation and sustainable development.

GEG’s Waste and Recycle Management Program has introduced a range of environmentally friendly products and services to the market and has significantly minimized the environmental impact of its operations.

Over the years, GEG’s flagship properties have received multiple energy-saving awards and certifications. For example, Broadway Macau was certified the ISO 140001 Environmental Management System and Galaxy Macau was awarded the local CEM Energy Saving Concept Award. All these certifications and awards serve as recognition of the GEG’s achievement in energy conservation.

MEIKO's journey with Galaxy Macau, one of GEG’s flagship properties, began in 2015 when Executive Chef Jon Hollands drove the project to find new dishwashing options for its busiest staff canteen. The workload here had increased over the years as Galaxy Macau expanded and the old dishwash system struggled to cope.

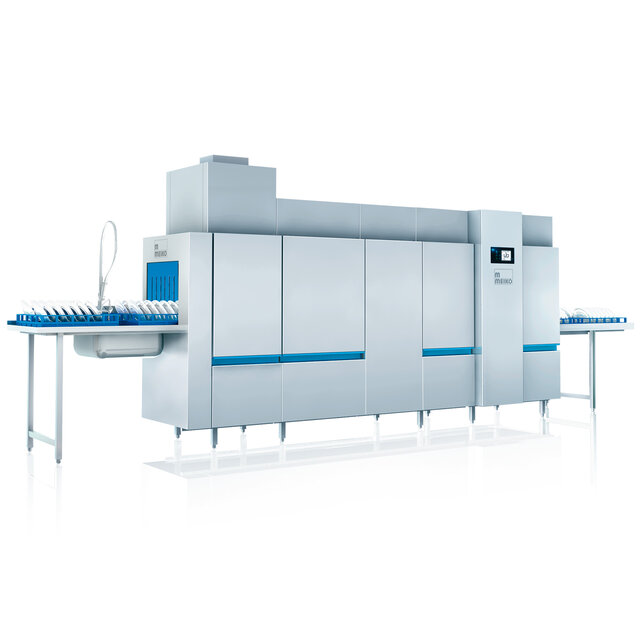

The dishwash is in operation 24/7 and the original specification called for a new system that could process 15,000 tray sets per day on average, with a maximum capacity of up to 18,000 – or 12.5 trays per minute!

GALAXY MACAU’S FIRST AND UTMOST CONCERN IS HYGIENE AND SAFETY.

Explains Bruno Correa, Vice President, Culinary, F&B Operations & Culinary, Galaxy Macau, “The new MEIKO system has delivered a remarkable improvement in capacity and in the sanitation of the dishwash process. Consistent wash and rinse temperatures together with thorough washing and rinsing ensures that our dishware, glassware and cutlery dry quickly and are safe from protein and chemical residue.”

The working environment has improved thanks to the heat recovery condenser units on the new dishwashing machines which have lowered humidity. The average ambient temperature is now 23-25°C, instead of the 32°C+ the site to experience. There is also less moisture on the floor, which helps ensure the safest possible working conditions.

MEIKO became the preferred choice for GEG by its reputation and quality of machines. The new dishwashing system has contributed a approx. 25% reduction in manning over 24-hour period and chemical usage has reduced by more than 10%. The heat recovery condensers help cut energy costs, providing cheaper utility bills.

Continues Correa, “They have been working with many large organizations requiring high volume dishwashing with a fast turnaround. A quick turnaround time can save us from purchasing additional equipment, which lowers costs and contributes an environmental saving.

“MEIKO’s regional office in Hong Kong also provides us with after-sales technical support, which is a key factor in the final decision.

“GEG is committed to protecting the environment and MEIKO is a valued partner in achieving this goal and regards MEIKO as a satisfying service partner which continues to develop innovative environmentally-friendly technologies.”

PROJECT MANAGEMENT

"We are delighted to be involved in this project through the design, planning, logistics, implementation and after-sales service and to have achieved high satisfaction from Galaxy Entertainment Group,” says Louis Lam, General Manager of MEIKO Clean Solutions Hong Kong Ltd.

The project began in 2015, when Galaxy Entertaining Group in Macau contacted MEIKO with regard to replacing their dishwashing system.

Louis Lam, together with MEIKO Deutschland's Christine Lapp and Frank Polauke made the first trip to Galaxy to examine the scope of the project. Following the design and planning stages, the new equipment was delivered and installed by the end of Jan 2017, before Chinese New Year. Handover was completed in February, following staff training and induction to the new system.

"It was truly a team effort among Galaxy Macau, MEIKO’s Macau dealer and service provider Chiming Engineering, MEIKO Deutschland and MEIKO Hong Kong to make this system changeover successful within a tight time-frame,” says Louis Lam.

“The MEIKO subsidiary in Hong Kong not only allows us to readily support Galaxy Macau with manufacturer expertise, but also to provide Galaxy with fast responsiveness for local implementation.”

MEIKO AND CHIMING ENGINEERING WORKED TOGETHER TO PERFECTLY FIT THE UPGRADED DISHWASH SYSTEM INTO THE ORIGINAL AREA.

This involved clever re-design of the dishwash area itself, but also some modifications to equipment.

Alterations carried out included re-positioning the legs on the BTA 240 tray washing machine to accommodate floor drainage and modifying the food waste flushing trough for the AZP 80 dewatering system to suit the site conditions.

THE LIST OF EQUIPMENT INSTALLED INDICATES THE HUGE VOLUME OF WARE INVOLVED.

Key items include:

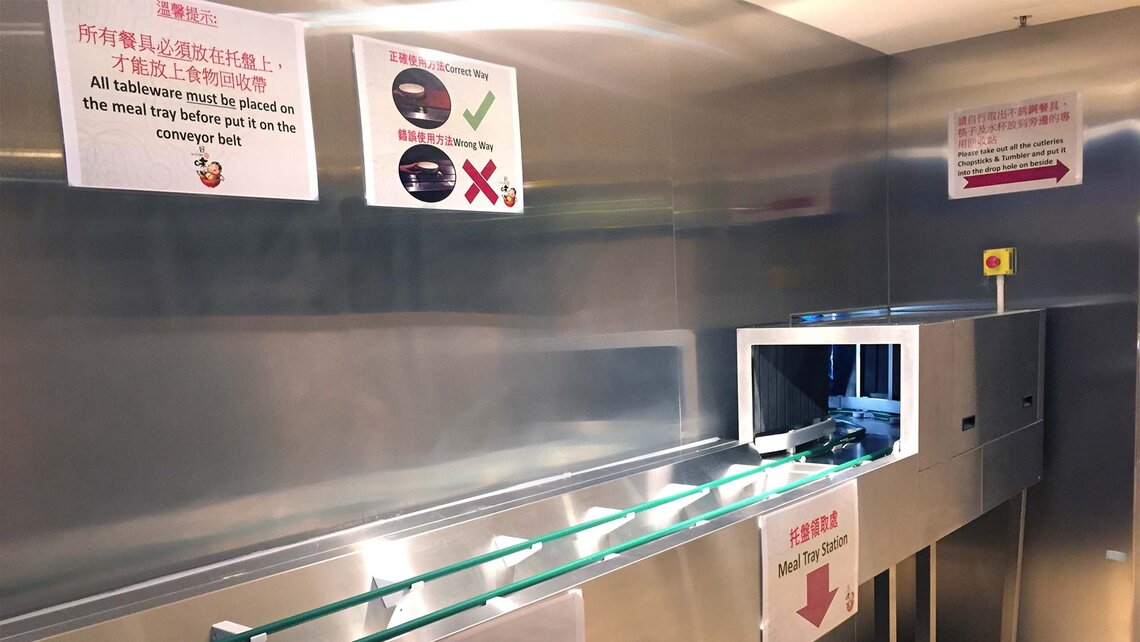

- Tray-onset/stripping conveyor

- BTA 240 Tray washing machine + Tray stacking device

- Tray stacker

- Automatic cutlery sorting unit

- M-iQ B-L54 V8 N02 P8 dish washing machine

- M-iQ B-M75 B N08 P8 pot washing machine

- M-iQ K-M54 V8 N04 P6 glass washing machine

- AZP80 Waste treatment unit, with flushing trough. This dewatering system reduces the volume of food waste by up to 80%, cutting road miles by reducing the number of waste collections and also cutting the labour needed to move waste around the site. The number of plastic waste sacks will also be considerably reduced.