Seymour Hotels of Jersey is responsible for 10% of Jersey’s bed stock and its portfolio includes the Merton Hotel and Suites, the Pomme d’Or Hotel and the Greenhills Country House Hotel.

Energy-saving is one of Seymour Hotels’ key priorities and a £5million investment programme prepared the hotels for the summer season. Almost half the investment, £2.3m, was spent moving from steam to low-temperature hot water systems at the Merton Hotel, providing major environmental and economic savings. www.seymourhotels.com

“Over the last decade we have reduced oil consumption across the Merton complex by about 35%, by introducing better controls, processes and making a significant capital investment in energy saving equipment,” explains Group Maintenance Manager, Seymour Hotels of Jersey, Dave Donoghue.

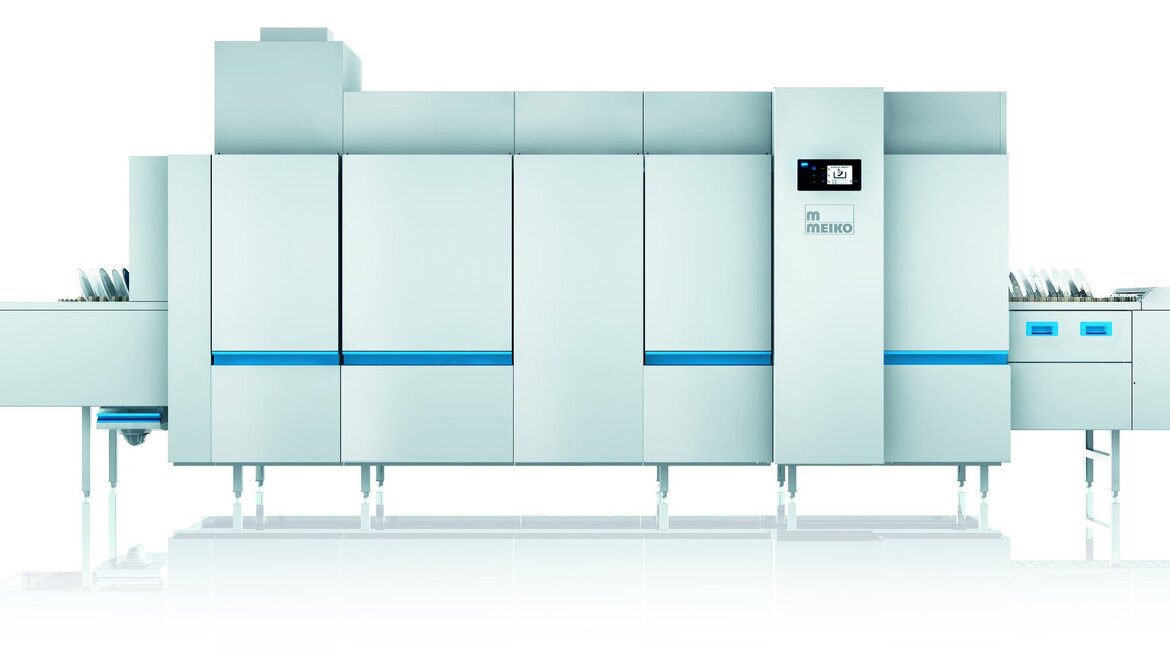

An energy-saving investment in catering equipment included replacing the large commercial dishwasher systems at two of Seymour Hotel’s properties, the Merton Hotel and Pomme d’Or Hotel.

“We have always had a good working relationship with MEIKO,” continues Dave Donoghue. “I was Senior Engineer here before my appointment as Seymour Hotel Group Maintenance Manager and knew all about the quality of the MEIKO machines and how well they performed.”

MEIKO’s new generation of commercial dishwashers deliver significant energy, water and chemicals savings compared to the previous generation.

“In terms of energy and water savings, we do not monitor the machines separately from the rest of the hotel, but there are noticeable differences,” says Dave Donoghue. “There is a noticeable improvement to the air quality in the dishwash areas, chiefly thanks to the integral heat recovery systems on the new

machines.

“I am certain also that we are saving significant amounts of energy and water…I am just unable to quantify that.”

“We looked at what the competitors had to offer when it came to replacements, but we decided to stick with MEIKO because of their machine build quality, reliability and the good technical support.

Being in Jersey, we can be stuck out on a limb sometimes with not having MEIKO engineers to attend to breakdowns, but MEIKO engineers always answer their phones to us and help my own team of engineers as much as they can. We talk through technical issues over the phone as and when they occur, and spare parts are quick and easy to order.”

MEIKO has calculated the savings between the old and new MEIKO commercial dishwashing machines at the Merton Hotel at a 40,880 k/W annual saving on electricity and 322,660 L annual saving in water consumption.

EXAMPLE OF ENERGY AND WATER SAVINGS, BASED ON ELECTRIC POWER SUPPLY

| Model | Old MEIKO B190 CSS top | Replaced with M-iQ B-M54-V6-P6 |

|---|---|---|

| Capacity plates/h for 2 min. contact time according to DIN 10510 Average energy consumption 12 hours daily use/365 days/cold water in at 10degC | 2000 | 2400 |

| Total electricity kw: | 33kw/hr | 23.5kw/hr |

| Water consumption | ||

| Final rinse water | 240lt/hour | 165lt/hour |

| Tank filling x1 | 190ltr | 206ltr |

40,880 k/W & 322,660ltr annual saving