“THE WASH QUALITY IS AMAZING AND IT HAS REALLY HELPED TO SEPARATE CUTLERY, CUPS AND GLASSWARE, LEAVING THE BIG MACHINE TO COPE WITH CROCKERY AND TRAYS."

Ardingly College is an independent co-educational boarding and day school for boys and girls aged 2-18. Set in a beautiful 230-acre campus in the West Sussex countryside, Ardingly is one of the UK's leading independent International Baccalaureate schools and has a national reputation for breadth of learning and excellence. The College accommodates 945 pupils, aged from 2-18; the campus is shared with Ardingly Nursery and Pre-Prep School, Prep School, Middle School and Sixth Form. Pupils aged eight to 18 take their meals in the main dining hall, which serves approximately 2,500-3,000 meals daily. Careful planning is essential as the hall seats just 269. The lunch session, for example, is split into two, catering for Prep pupils from 12.25-1pm and Senior from 1.15-2pm.

“Ardingly College have been using MEIKO dishwashers for over 13 years and currently have five in operation,” says Catering Manager Jo Davis

“When the catering department needed to re-design the main wash-up area we went straight to MEIKO because of their ‘can do’ attitude and willingness to help us with the ergonomics, ensuring the wash up area was a safe and pleasant environment for staff to work in.”

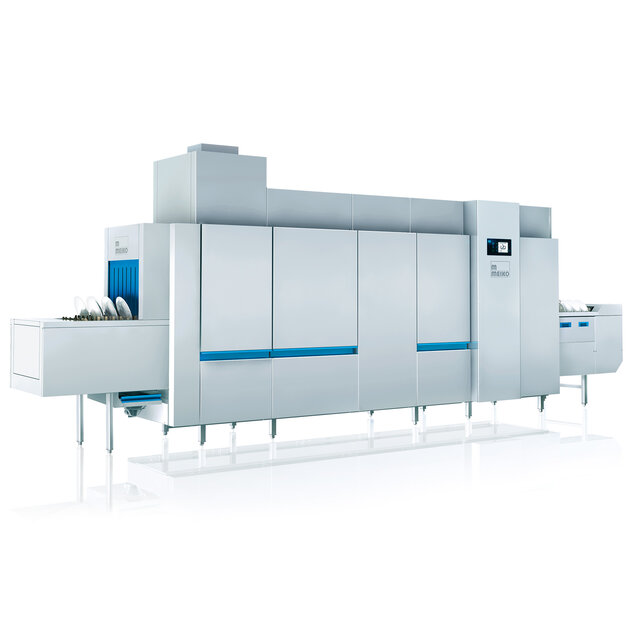

Emphasizing the ‘can-do’ attitude of MEIKO Regional Sales Manager Martin Pinder in particular, Jo Davis explained that Pinder worked in co-operation with the College’s Estates Department and Health & Safety staff to design a more user friendly and ergonomic dishwash area. The previous single dishwasher was a large MEIKO flight machine which had lasted 13 years! The College has a Five-Star Maintenance Contract with MEIKO which includes regular planned maintenance, parts and labour and quick responses in the event of breakdown. The new design now features two dishwashing machines and has moved the conveyor, which is now routed around the wall of the dishwash area. This allows two staff to decant trays directly onto the dishwasher’s conveyor belt with no undue bending or stretching.

A soak sink is used to store cutlery prior to washing in the DV 80.2 GiO AirConcept hood machine, which also handles cups and glassware. Tray lowerators help to save staff bending and stretching by collecting used trays as they come to the end of the conveyor. The trays are then easily moved around for washing at the end of service. Four staff operate the dishwash at breakfast time, five at lunchtimes.

Continues Jo Davis, “The wash quality is amazing and it has really helped to separate cutlery, cups and glassware, leaving the big machine to cope with crockery and trays." The staff love the self-cleaning cycle on the M-iQ which saves a lot of time.

“We have found our new dishwasher easy to use and to be one of the best on the market environmentally as well. It is now a quieter, safer and more inviting place to work in. Engineer call outs are also fast and efficient.”

New innovations such as the GiO integral reverse osmosis water treatment installed on the DV80.2 machine provide sparkling clean results and cut chemical consumption by providing the cleanest possible wash water. Reverse osmosis removes up to 98% of impurities from incoming water including mineral contaminants such as calcium. RO also makes the kitchen more sustainable because there is no longer any need for water softeners and all the salt and energy they consume.

Now available on MEIKO hood-type machines including premium dishwashers and utensil washers, the AirConcept will – in most cases – eliminate the need for an overhead extraction canopy, saving many thousands of pounds for the user. AirConcept captures exhaust heat and feeds the hot air back into the machine to pre-heat incoming cold water, as part of a heat recovery process.