Chang’an, or South Campus, is one of two campuses within Northwestern University which comprises 22 schools and departments, plus a graduate school. NWU has and about 2,500 members of faculty and staff. The student population of over 23,000 includes 7,000 graduates. NWU attaches great importance to international exchange and some 700 international students attend NWU.

Situated in Xi’an, an ancient capital of China and the start of the famous silk road, the city is also home to the Terracotta Warriors and China’s space exploration program. The catering building includes a first-floor staff and student canteen for 3000 people; second floor is a local delicacies canteen for about 2000 people and the third and fourth floors are restaurants for 1000 people.

Before the installation of a new dishwashing solution by MEIKO Wash-Up Technologies Ltd., based in Zhongshan, Guangdong province, Chang’an Campus used traditional methods to clean and disinfect cutlery and dishes and the food waste was handled manually. The old system involved keeping a large reserve of cutlery and dishes and the use of disinfectors for cutlery disinfection. MEIKO warewashing systems were selected because of their excellent washing results, combined with labour and cost-saving benefits.

MEIKO Wash-Up Technologies provided an integrated warewashing and food waste handling solution. Operating costs and labour have both been reduced, as has the large reserve of cutlery and dishes. Before the installation of a new dishwashing solution by MEIKO Wash-Up Technologies Ltd., based in Zhongshan, Guangdong province, Chang’an Campus used traditional methods to clean and disinfect cutlery and dishes and the food waste was handled manually. The old system involved keeping a large reserve of cutlery and dishes and the use of disinfectors for cutlery disinfection. MEIKO warewashing systems were selected because of their excellent washing results, combined with labour and cost-saving benefits. MEIKO Wash-Up Technologies provided an integrated warewashing and food waste handling solution. Operating costs and labour have both been reduced, as has the large reserve of cutlery and dishes.

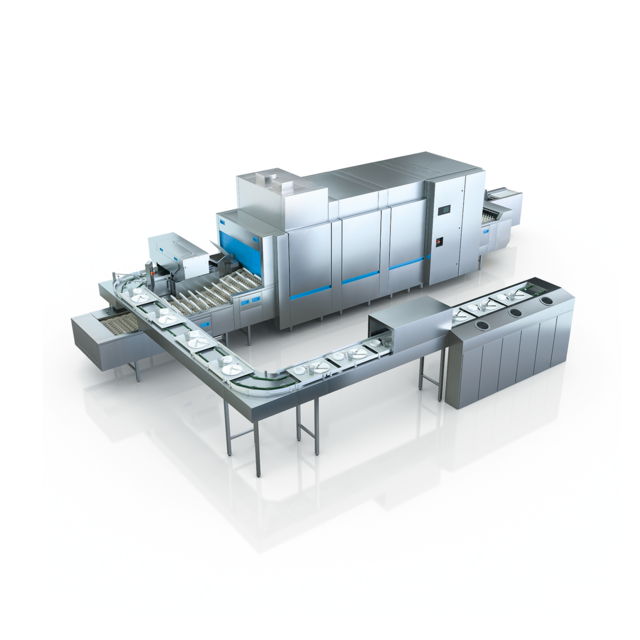

First and second floor facilities include MEIKO B690VAP-CSS-Top flight dishwashers, with Bi-Cord conveyor and AZP 80 food waste dewatering unit with flushing trough, for a washing capacity of up to 7,000 plates per hour. Waste food is scrapped into the flushing trough which feeds the AZP. In turn, the AZP reduces volume of the food waste by up to 80 per cent, creating significant savings in labour, transport and storage. Third and fourth floor facilities utilize MEIKO B190P flight dishwashers with throughputs up to 2,000 plates/hour.

The CSS-Top system effectively helps to reduce chemicals consumption by up to 80 %. Additionally, incorporating CSS-Top increases warewashing throughput by approximately 20 %, bringing further savings on energy and water consumption.