It is a Swiss peculiarity that brings wearers of respiratory protective equipment into the respiratory protective equipment workshop: here, it is standard for every firefighter to clean and inspect his or her own mask – at least after training. In 2018, mask manufacturers publicised the directive requiring regulators to be disinfected, too, meaning there is a need for many Swiss respiratory protective equipment workshops to change how they do things.

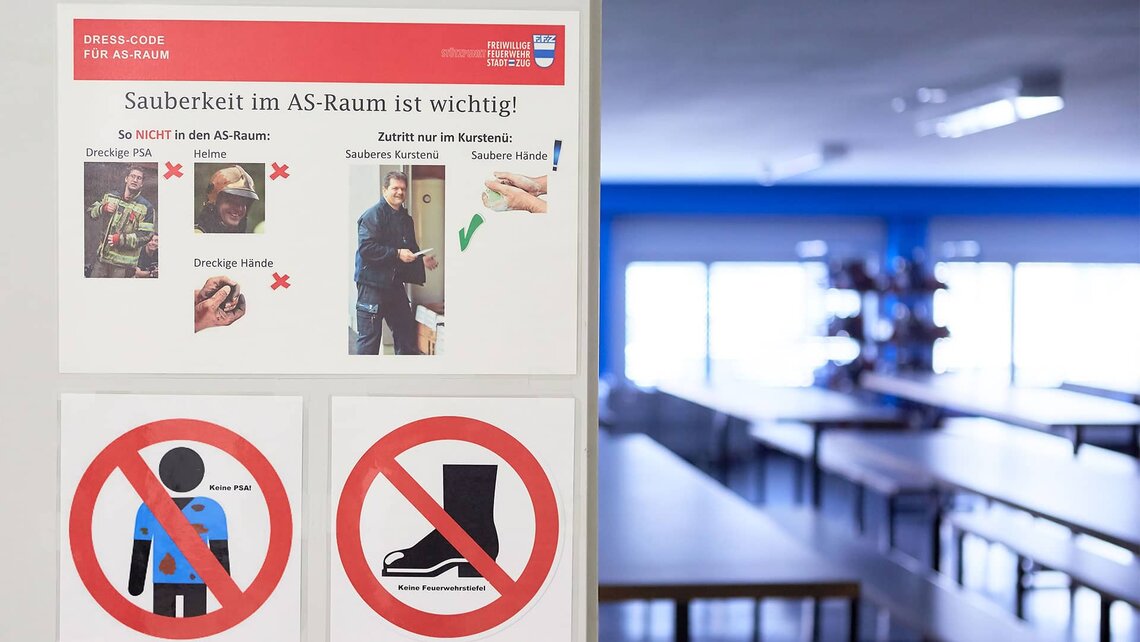

Samuel Schmid tells us. He is head of the logistics department at Zug voluntary fire service and he is one of five respiratory protective equipment technicians employed by the service. That means he is one of the people cleaning his colleagues' BA masks using Zug's TopClean M cleaning and disinfection machine for respiratory protective equipment by MEIKO. ‘We've got an assured process, reliable results and we don't have to do it all by hand anymore,’ he says, recounting the benefits of the TopClean M cleaning and disinfection machine for respiratory protective equipment. Zug voluntary fire service has 65 masks in circulation. It was a mask manufacturer who told the respiratory protective equipment technicians that these masks could be cleaned much faster, more conveniently and more reliably in a machine, thanks to MEIKO. Now the machine separates the clean and dirty areas of Zug's respiratory protective equipment workshop. It has become an important way to protect these men and women, who risk their lives in emergency situations, from fire-related cancer.