REDUCING WATER

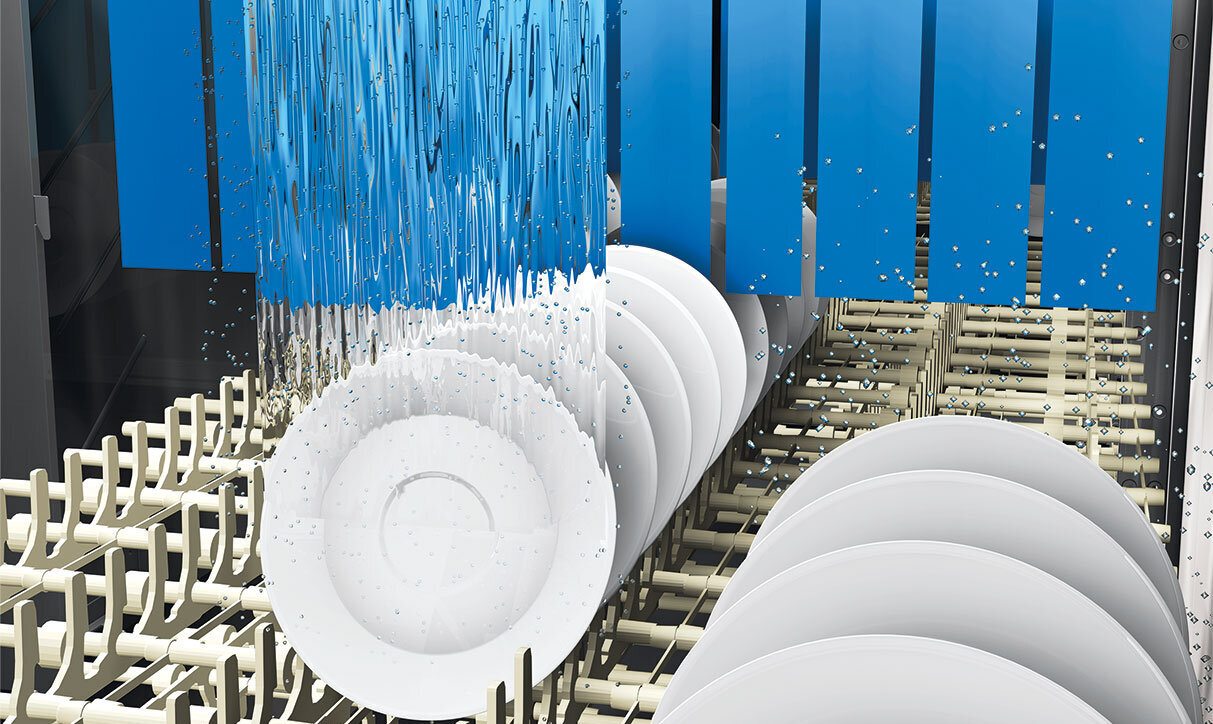

But first, let’s study the history of water use reduction in using dishwashing machines. In 1978, 83 percent of a dishwasher's energy was used for heating water; 10 percent of it was used for washing; and 7 percent for drying. By year 1994, there was a significant improvement – only 56 percent of energy used by a dishwasher was used to heat water. The reason behind is more efficient wash systems were designed by manufacturers to incorporate improved soil-handling systems and direct water delivery into a dishwashing machine.

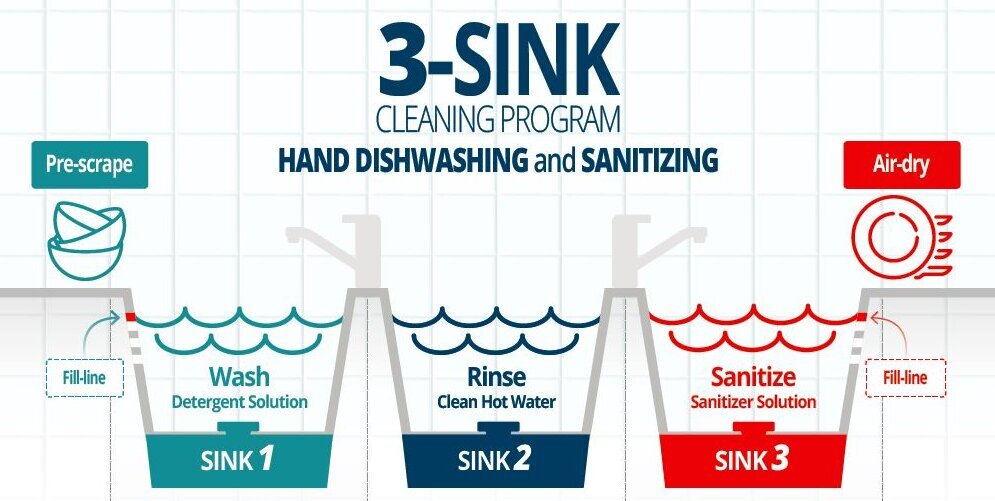

And of course, we cannot ignore the hard facts of “manual dishwashing” – many restaurants still resort to the “3-sink method” of manual dishwashing.

But do you know that using a dishwashing machine generally saves up to 60 percent of energy compared to manual dishwashing?

Dishwasher technology has improved dramatically over the last decade. Thanks to the improvement, the new dishwashing machines are designed with innovation in mind - to primarily reduce energy and water consumption as well as to improve performance. So, don’t be surprised when you come across dishwashing machines that comes with automatic adjustment of water consumption and continuous monitoring of water. Well, technology is moving faster than our times anyways. So, why shouldn’t you as a foodservice operator (or a decision-maker) demand these functions from a dishwasher when purchasing one?

REDUCING HEAT

It isn’t only about the water, really. Of course, less water consumption by a dishwashing machine means less use of energy. But saving resources from using a dishwashing machine also translates to reducing the use of heat. Here’s a valuable advice by the Office of Energy Efficiency & Renewable Energy, U.S.:

Check the volume of service and size the dishwasher accordingly. Be sure to consider the energy trade-off associated with increased tank heat that may be required for larger machines.

What if we told you there is a solution to that, or rather an intelligence of a special kind to address this concern, and it’s known as “heat recovery”? Heat recovery typically consists of heat source, cold water and a heat exchanger that allows the transfer of heat. The resulting condensation effect boasts many advantages and is a key feature of some of our commercial dishwashing machines.

MEIKO’s heat recovery technology through Air Concept is an innovative approach to air management. It generates top-class air quality by recovering the heat from exhaust air and transfer them to heat up the machine, instead of releasing it uncontrollably into the room. Through this technology, the dishwashing machine is required to generate less heat, reducing the dishwashing machine’s power consumption and achieving substantial energy and cost savings. In other words, when passed through the heat recovery module, energy consumption is reduced to a very low level. Not only that, the process also improves the indoor climate of the dishwashing area or dishwashing room, giving it a transformation in ambience and as a working environment.

REDUCE RESOURCES, BUT DON’T REDUCE CLEANLINESS…

As a hospitality operator, you may want to reduce energy consumption but not cleanliness in dishwashing. Dishwashing machines such as MEIKO’s M-iQ strikes the perfect balance between cleanliness, efficiency and minimal resource consumption. A unique leap for the technology of dishwashing – check out more on how you can manage energy effectively and efficiently when using a dishwashing machine here.

Source: MEIKO Asia, Webstaurant Store, Journal of Extension