THE 1920S

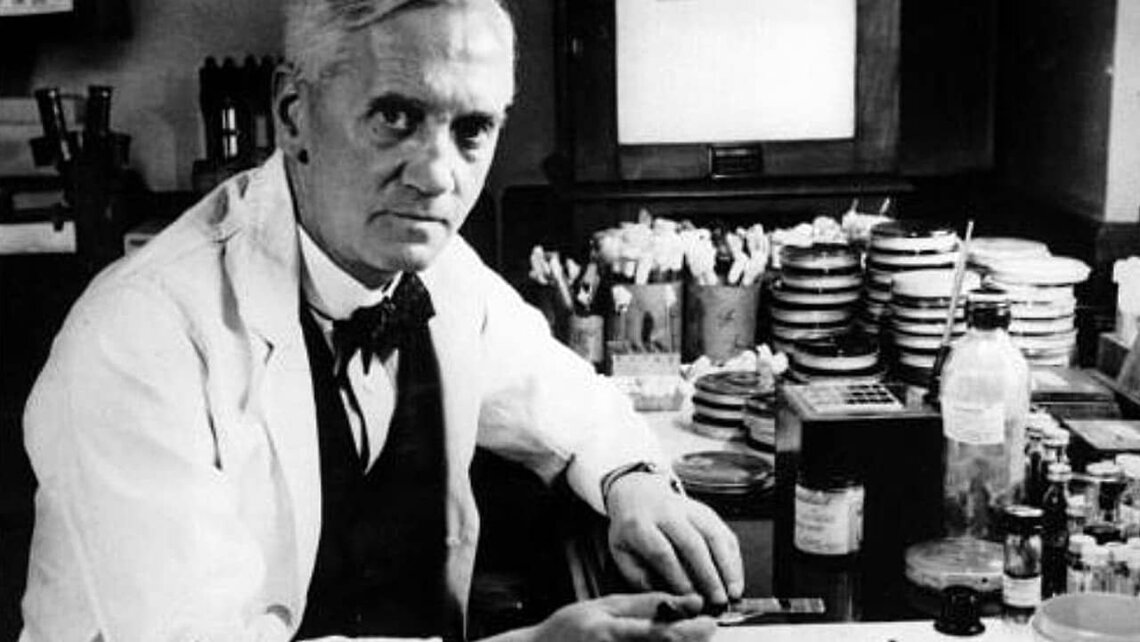

Pioneers of a cleaner world

1927

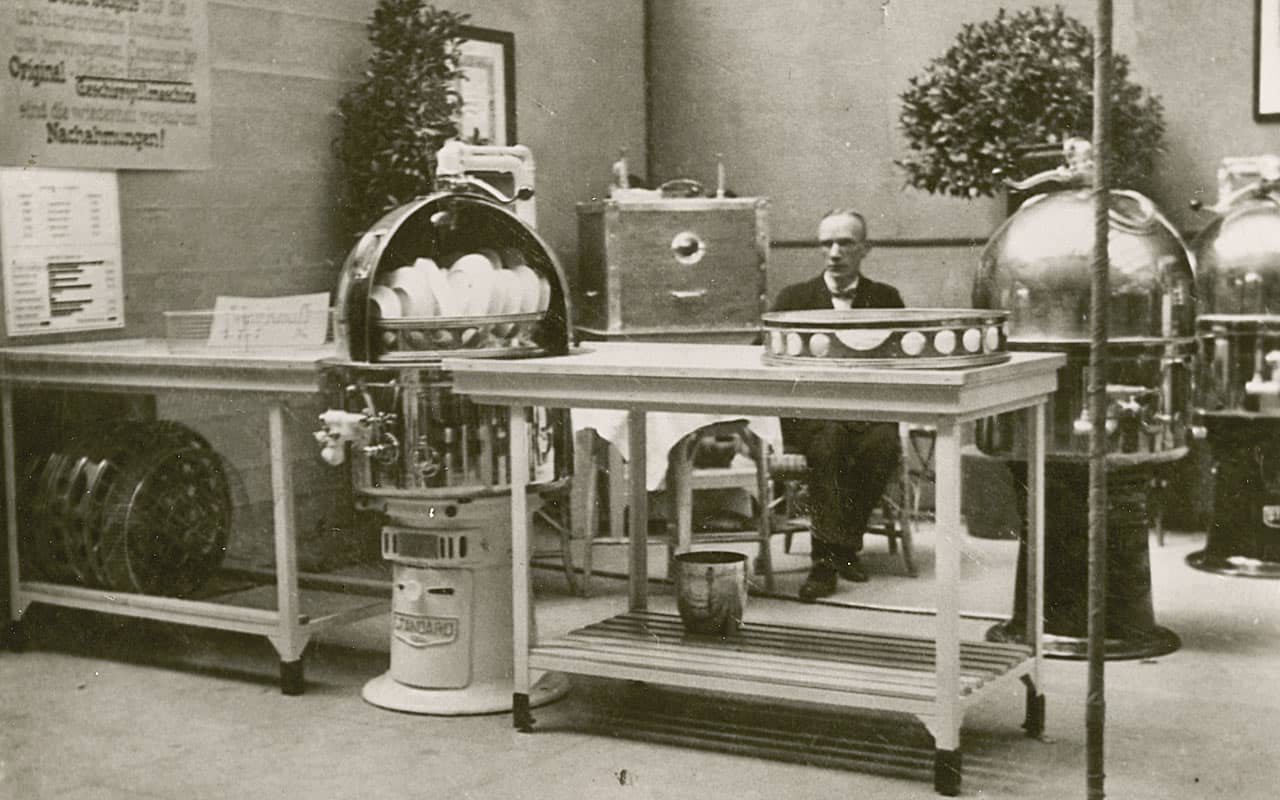

The founding

The company „MEIKO Maschinen und Apparatebau“ is founded. Great cleaning starts with the founders’ vision of „making the world a cleaner place“. MEIKO builds the very first professional dishwashing machine (the „Standard DRP“ model) which becomes a huge seller all across Europe. The company lays the foundations for high export sales right from the start. Today, exports account for 60% of its sales.

Between 1927 and 1950, MEIKO produced machines with wonderful names such as Konstanze, Monika and Erika. Monika was the successor to the original „Standard DRP“ model.

1928

The product range is being extended

MEIKO increases its range of products, manufacturing and offering new additions including tables and counters for commercial kitchens, specialist food processors for tasks such as grating, chopping, stirring, mixing and whipping, and water heaters.

THE 1930S

A turbulent period of integrity and ingenuity

1934

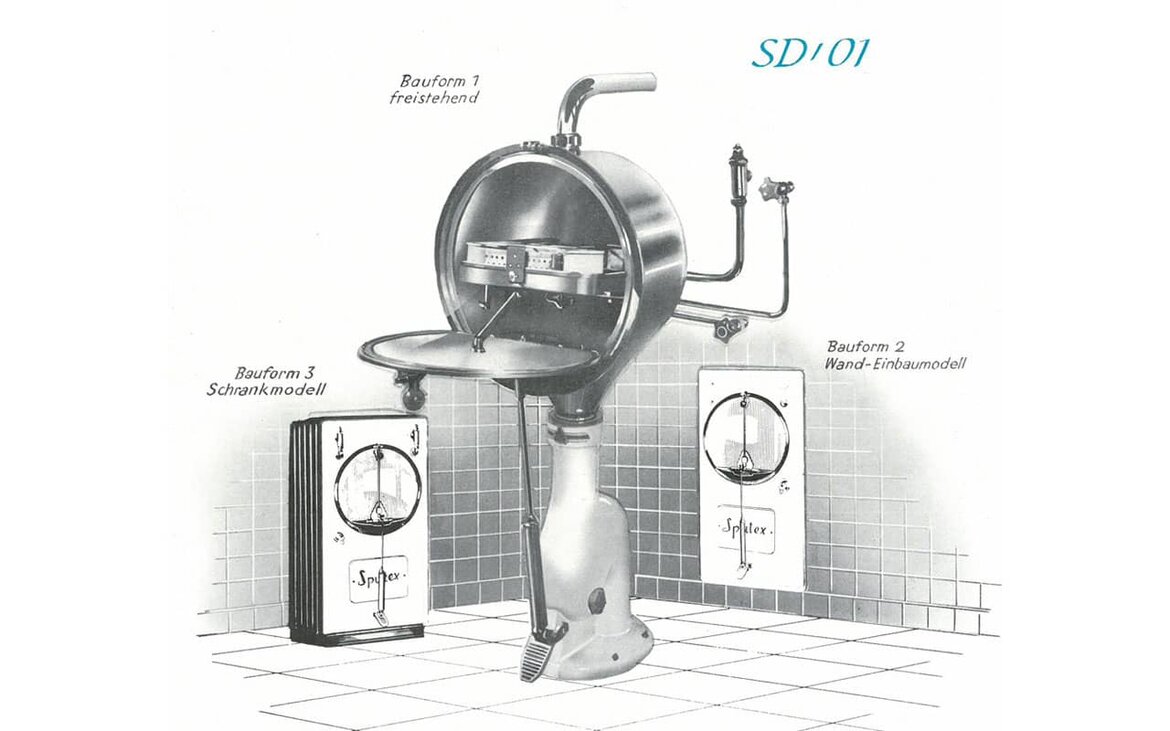

More Products for hospitals & nursing homes

MEIKO starts making „emptying, washing and disinfecting machines“ for hospitals and care homes. After the war, the models initially retained the same basic look. It wasn’t until many years later that their design was completely overhauled. Nowadays they are generally referred to as bedpan washer-disinfectors.

1937

Oskar Meier becomes sole owner

Oskar Meier is keen to leave MEIKO and start up a new company to make refrigerators. The idea is for Franz Konrad to take sole charge of MEIKO – but things don’t work out as planned. On 17 September 1937, Konrad is taken into custody by the Gestapo. He had been denounced by an apprentice after criticising the Nazi regime and Adolf Hitler in front of his employees on numerous occasions. Charged, detained and ultimately acquitted, Konrad has to sell his stake in MEIKO in 1938 to stop the company losing its government contracts. The two MEIKO founders agree that Konrad should receive a payment of 65,000 Reichsmarks. In 1940, he opens an ironmongers in the Polish city of Kalisz.

THE 1940S

Destruction – and a new beginning

1940

Rack type dishwashing machines are launched on the market

People are looking for new solutions to deal with larger amounts of dishware, especially in restaurant and catering environments. The aim is to run the dishwash area smoothly and efficiently and avoid piles of dirty dishware. To meet this challenge, MEIKO launches a new product in the early 1940s: rack type dishwashing machines. They are an immediate hit, and they continue to sell well today. At that time, the focus was still firmly on automatic machines and appliances.

1944

Complete destruction & Reconstruction

MEIKO doesn’t escape unscathed from World War II: on 27 November 1944, the company is completely destroyed by an aerial bombardment and production is temporarily shifted to Zunsweier. The following years are particularly tough. Some employees have been captured as prisoners of war, and the company struggles to rebuild things from scratch. Some of those held in captivity return to the company after their release.

1945

Post-war period: New Contracts

The post-war period sees the company engage in some very different kinds of work. Faced with a scarcity of resources, MEIKO workers strip down railway freight cars and passenger carriages that were destroyed in the fighting to reuse their parts. Work also comes from the occupying powers, including contracts to clean up the debris along railway lines and rebuild the prison in Offenburg. Getting hold of the materials needed to make machines is extremely difficult. MEIKO Ettenheim specialises in taking apart the remains of old aircraft. Aluminium is particularly sought-after as a raw material for making pots, pans and spaetzle presses. A brisk bartering trade is up and running. Oskar Meier spends a period working as the factory manager at the company Nestler in Lahr, which made pots and pans.

1948

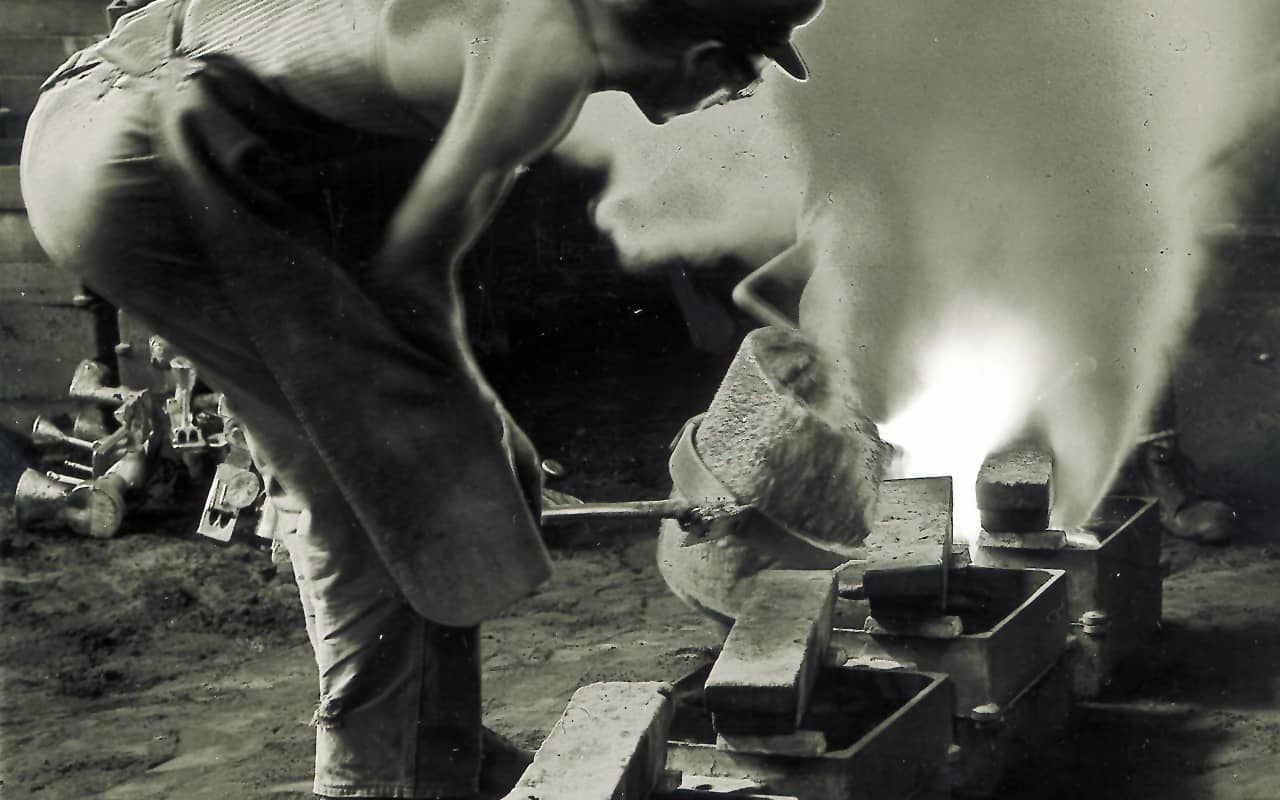

New part of the company

An iron and metal foundry is set up in Ettenheim and incorporated as part of the company. This benefits MEIKO enormously, because the company mostly relies on acquiring cast parts, stopcocks and valves made from grey cast iron in order to install them in dishwashing machines and medical devices. Today, the Ettenheim iron foundry employs 50 people, including two apprentices. It makes a range of products including injection molded parts, pumps, fittings and gear units as well as application-specific components.

THE 1950S

A flourishing period of research

1954

Two new machines

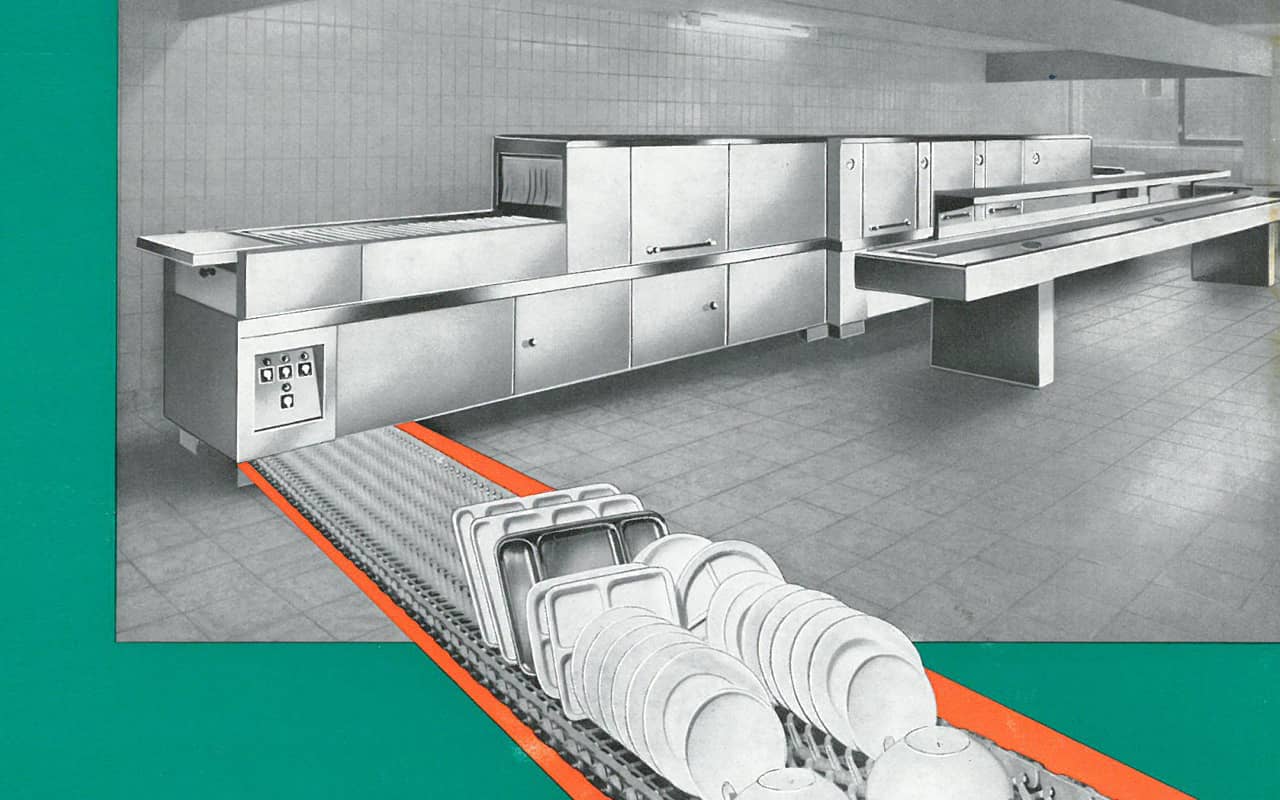

The 1950s mark the launch of the MEIKO SE 100/U, which becomes a huge export success. Its innovative features include a chainless conveyor for dish racks and baskets as well as a steam condensing system and a dishware drying system. It soon becomes Europe’s best-selling machine based on a circulating pump – a genuine dishwashing marvel! But MEIKO doesn’t stop there. Its next step is to launch a flight type dishwashing machine, which also proves to be a great hit. The success of this popular type of MEIKO dishwashing machine began in 1954 with the BA 125 and still continues today with the M-iQ range.

THE 1960S

Ups and downs in Offenburg

1960

Individual Solutions

The EE60 heralds a new generation of hood type dishwashing machines – and it takes the market by storm. Its success stems from how it makes life so much easier for machine operators. The magic word ergonomics is already on people’s lips. The goal is to put less strain on people in the workplace – and that’s a philosophy that MEIKO continues to pursue today. But the company focuses on more than just washing dishes. MEIKO has started making special washing machines to clean handsets from public telephone booths for the German Post Office, and even comb washers for a comb manufacturer! It is also reaching out beyond high-volume production to place more of an emphasis on tailored solutions for individual customers.

1963

Cleaning bottles on maternity wards

MEIKO sees the establishment of a „representative body under the works council constitution act“ to take charge of employee representation.

Things are also moving fast in terms of machine development: the ST 60 and ST 80 front-loading machines are launched as a compact option for confined spaces with ergonomic loading at table height.

MEIKO also launches its new MD 20 model to wash bottles on maternity wards and sterilise them with UV technology, which proves to be another big seller.

1964

New materials complement the production

New materials start to change the way MEIKO works. Stainless steel and plastics gradually replace the more corrosion-prone brass as the best materials for making its machines. The first pot and pan washers are showcased at Internorga in Hamburg and MEIKO becomes the first German machine maker to offer rack type dishwashing machines with motorised curved tracks and an extensive range of tabling systems. As well as introducing the first plastic peg rack for commercial dishwashing machines, MEIKO also adapts its dishwashers for ocean-going vessels, prompting the first deployment of a BA K80 flight type dishwashing machine on a German Armed Forces warship.

1965

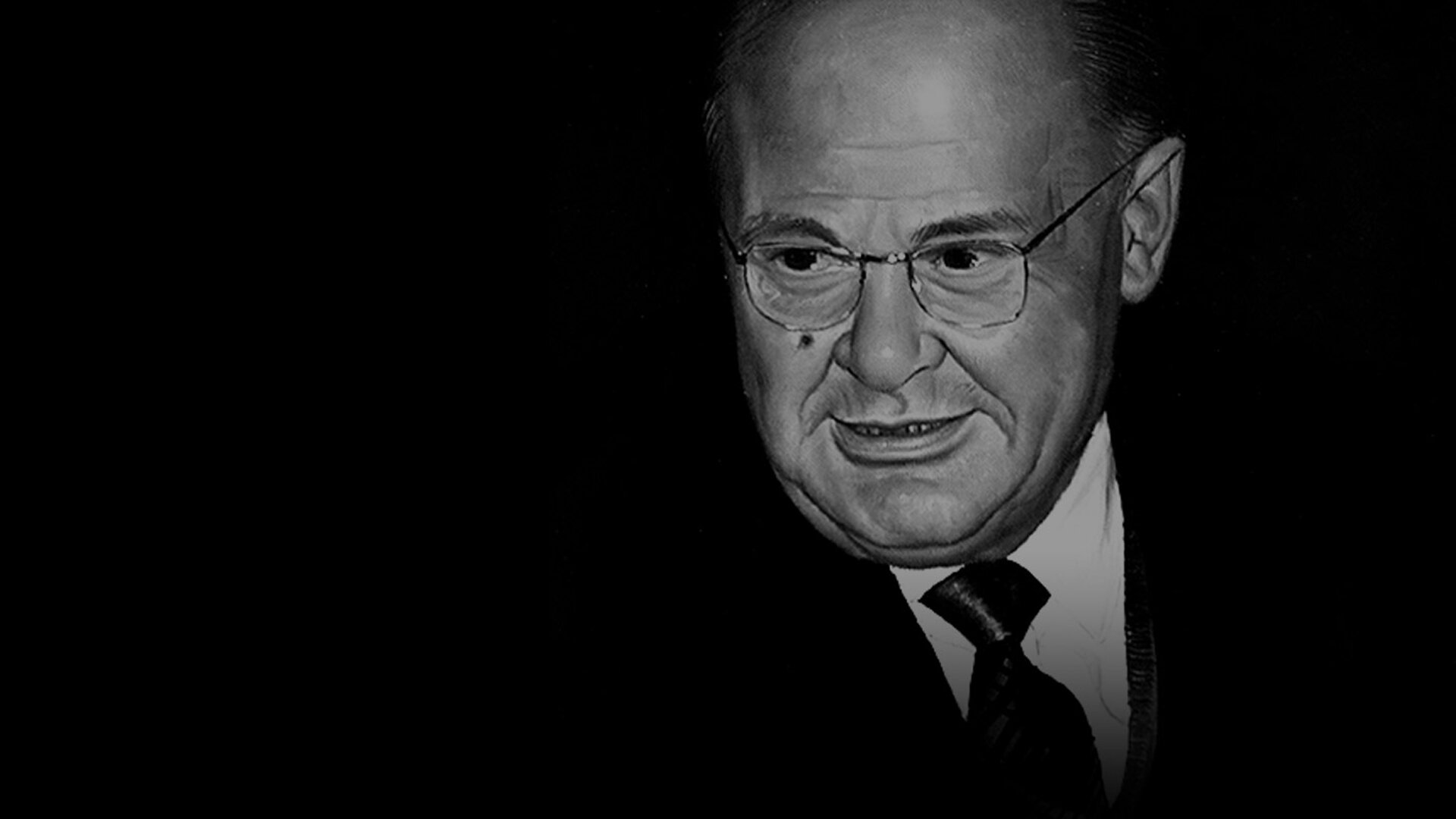

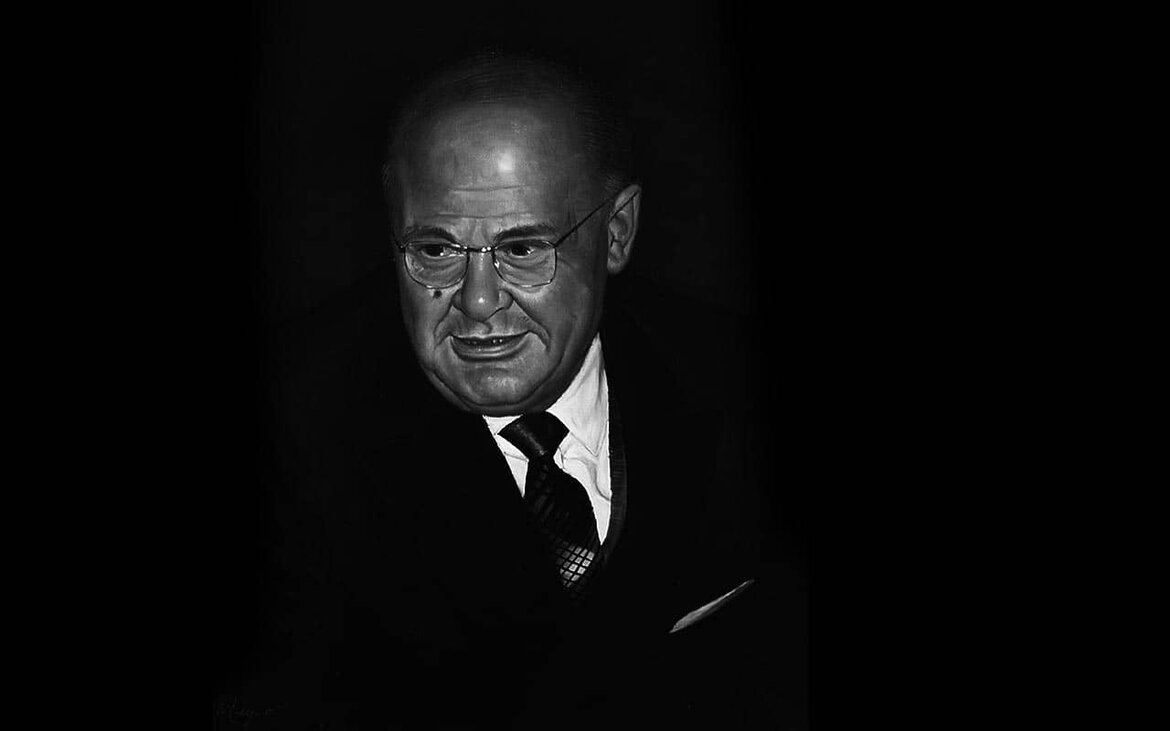

New Leadership

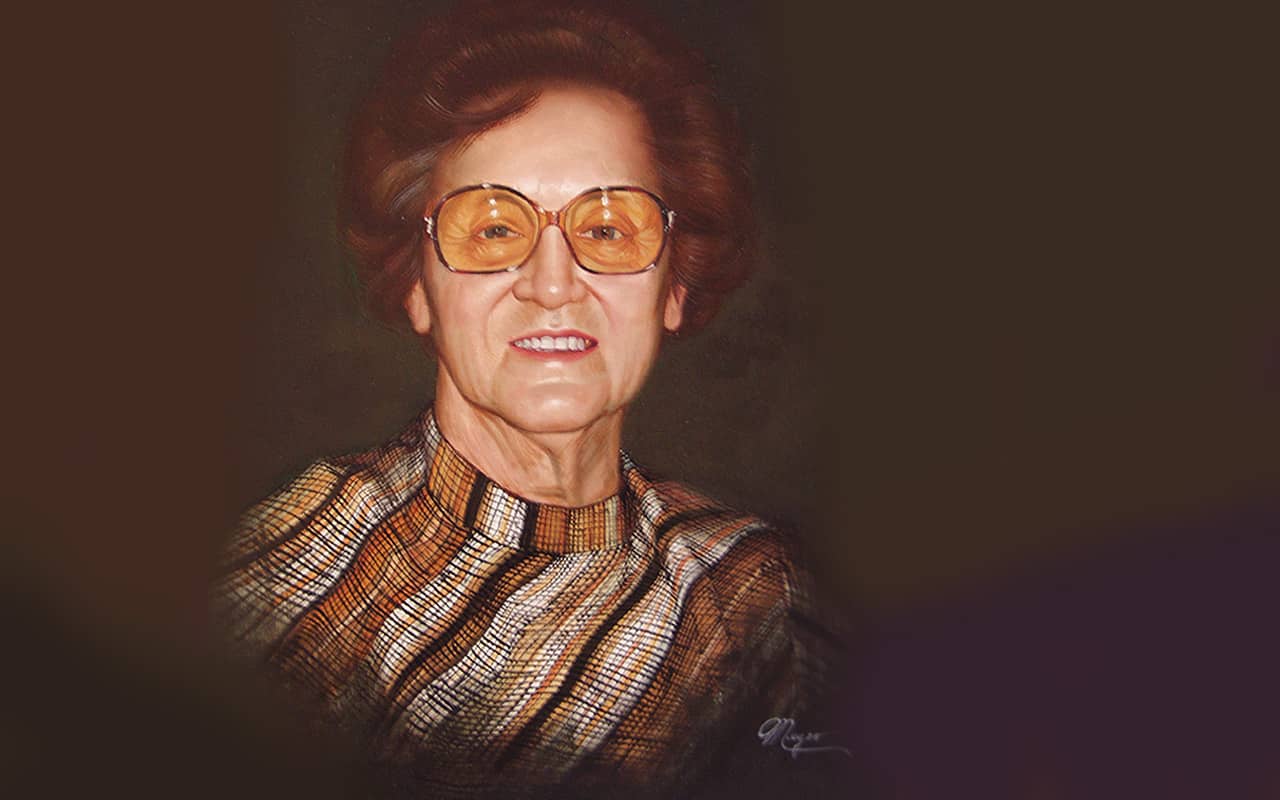

The company mourns the loss of Oskar Meier, an extraordinarily creative visionary and a managing director with a human touch. The company’s fate now lies in the hands of Heinrich Menges and Rosel Meier. It’s an emotional time for everyone who works at MEIKO, but they press ahead with even more new developments and space needed between innovations. The company puts serious thought into how they can make life easier for its customers and solve the challenges they face. This leads to the development of the water hydraulic dish rack lifting and lowering device for improved ergonomics as well as laboratory washers and washer-disinfectors.

1967

Development & Research

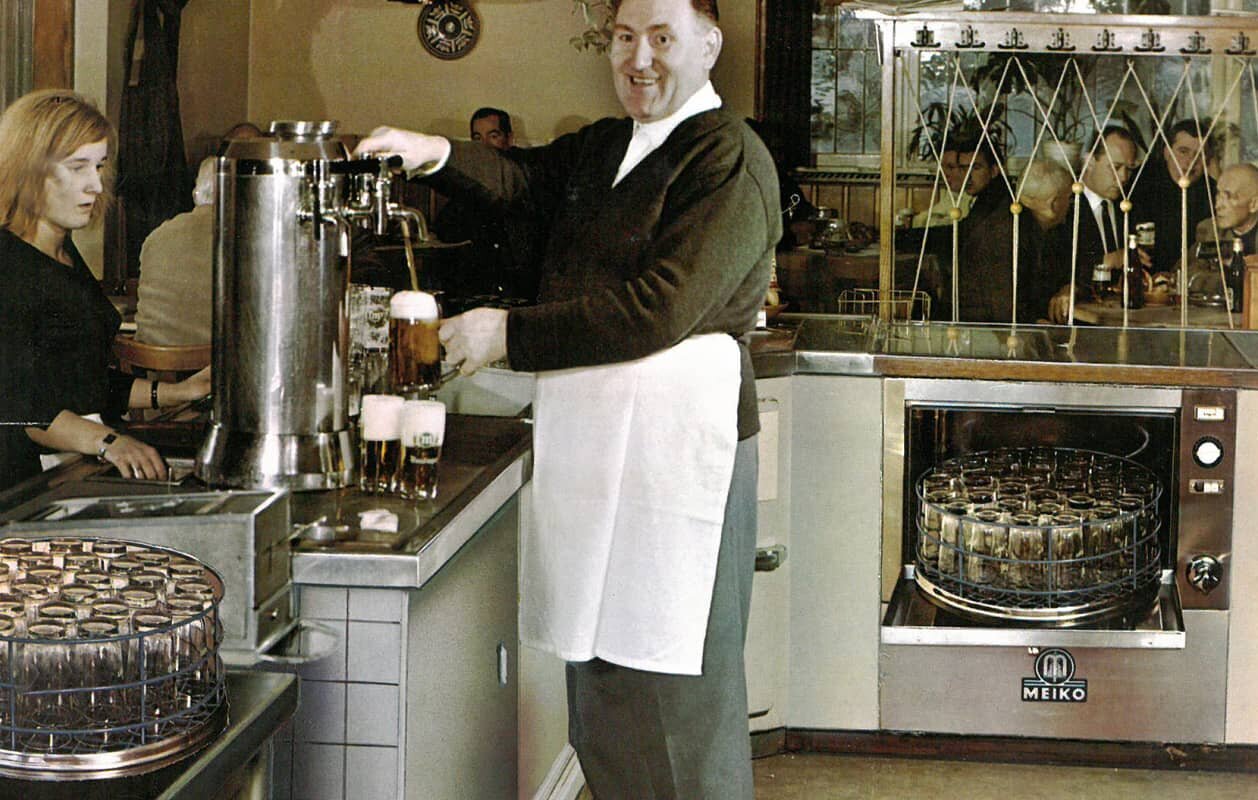

MEIKO is still powering ahead with its research and development programmes. MEIKO engineers make fantastic progress with R&D in the 1960s, experimenting with ultrasound and granules and achieving a further breakthrough in hood type dishwashing machines by switching from a curved to a rectangular hood. This period also sees the launch of the first compact glasswasher with a full demineralisation system. The company develops new water softening and full demineralisation units as well as dosing systems. It also launches a dual-basket dishwashing machine and installs the first conveyor system at the student refectory in Munich. More and more hospitals are providing meals to patients, offering the perfect opportunity to automate dishwashing systems with plate and tray stackers.

THE 1970S

For the good of the company and everyone who works there – a foundation is born

1971

Another success story

MEIKO celebrates gaining some 80% of the refectory dishwashing market and develops a range of new conveyor and automation systems. Other areas of the business are also developing fast, and the company launches its first electronic variable speed conveyor drive. Tests are also being conducted on a range of drying, extraction and steam condensation systems. The company is awash with inventiveness and ingenuity, but only a few of the ideas are put straight into practice. Some things require further development and will re-emerge at a later point in time.

1973

The oil crisis as innovation accelerator

With the oil crisis driving innovation, engineers develop and launch the first system designed to recover waste heat in conveyor dishwashing machines. MEIKO continues to focus on minimising the use of resources. In 2011, it receives the Baden-Württemberg Environmental Technology Prize for its M-iQ flight type dishwashers. This range of machines offers unparalleled efficiency and economy and proves to be a tremendous success. Oskar Meier would have been delighted with the creative flair and ingenuity shown by his engineers.

1974

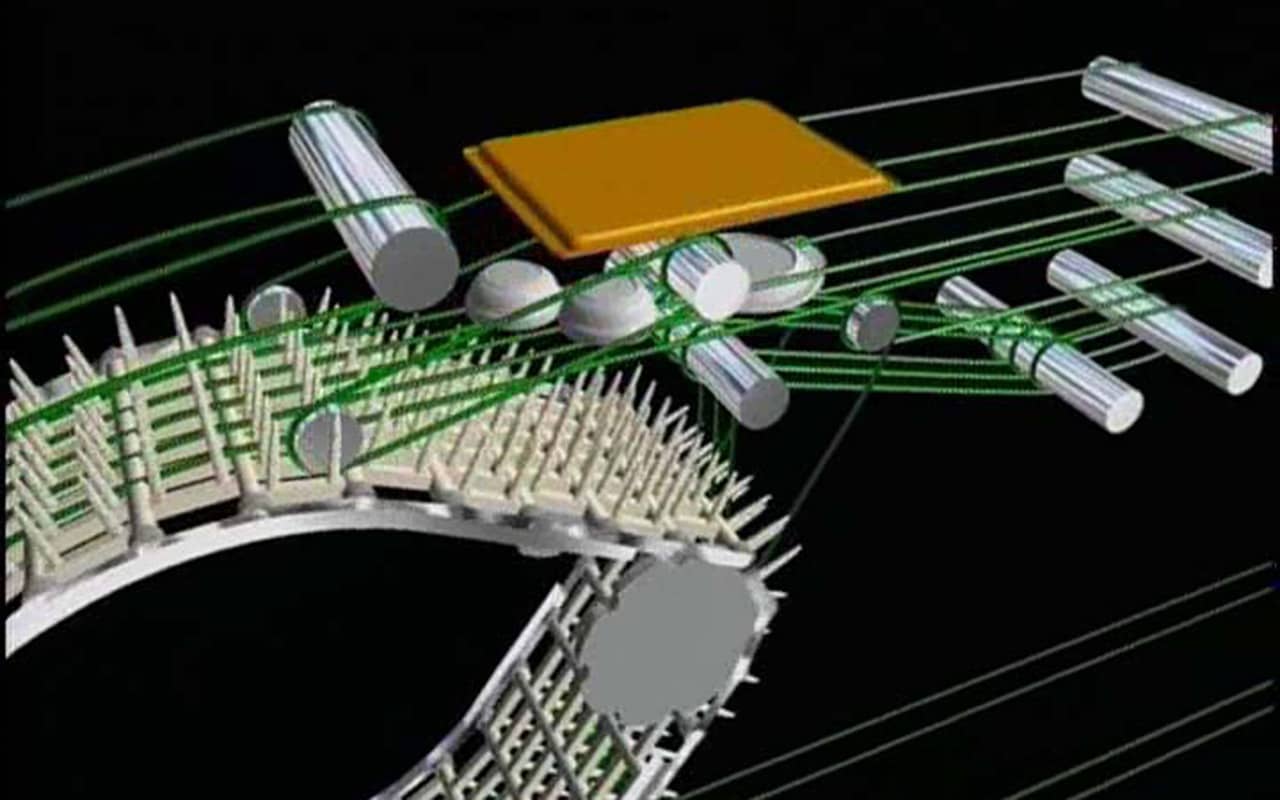

A small sketch changed the world

A spontaneous idea and a rough sketch by design engineer Willi Ritzenhoff heralds a major change in the world of fully automatic dishwashing machines. After trying a few things out on paper, Ritzenhoff and his engineering colleague Waldemar Kunzelmann make some rough calculations and take them to their production foreman Zind. He is convinced they have hit upon something worthwhile. That’s what prompted the company to embark on the design and manufacture of the world’s first fully automatic dishwashing system, which was launched soon after. At its heart was the company’s proprietary „hedgehog“ conveyor technology which handles clearing, turning and sorting tasks. The new system makes it possible to wash cutlery, plastic dishware and toughened glassware fully automatically.

1975

Synonym for cleanliness & hygiene

The production of medical devices has been one of the company’s greatest successes ever since the 1930s. MEIKO is becoming synonymous with cleanliness and hygiene in the field of cleaning and disinfection equipment. The year 1975 sees the launch of the new bedpan washer-disinfector KD-AP. As well as fulfilling all European wastewater directives, it is easy to install and boasts a modern design. The wash process is now controlled by a software programme instead of relying on a human operator. The machine also includes physical monitoring of the disinfection process. Bedpan washer-disinfectors are also known as washer-decontaminators and disinfection appliances.

1979

MEIKO become a Foundation

Rosel Meier passed away in 1979, and MEIKO’s managing director Heinrich Menges died just three weeks later. In her last will and testament she decreed that MEIKO should henceforth be owned and managed by a foundation. Faced with inheritance taxes of 23 million Deutschmarks, the new managing director Herbert Herp implemented a rigorous cost-saving program. Herp was succeeded by Dr. Ulf Starke in 1980. In 1980, the company had 400 employees and an annual turnover of 22 million Deutschmarks. By the time Starke left the company in the year 2000, these figures had risen to 850 employees and a turnover of 170 million Deutschmarks. From 2000 to 2014, MEIKO grew rapidly under the joint leadership of Burkhard Randel and Dr.-Ing. Stefan Scheringer. Randel is now the chairman of the Foundation’s board of trustees while Dr.-Ing. Scheringer has continued in his leadership role as the sole managing director. In 2016, MEIKO generated over 320 million euros in sales revenue. On 1 July 2021, Dr. Stefan Scheringer moved from the position of CEO to the Foundation Board of the Oskar and Rosel Meier Foundation after 21 years. His successor will be the long-standing CTO Dr Thomas Peukert.

THE 1980S

Ahead of its time

1980

New developments

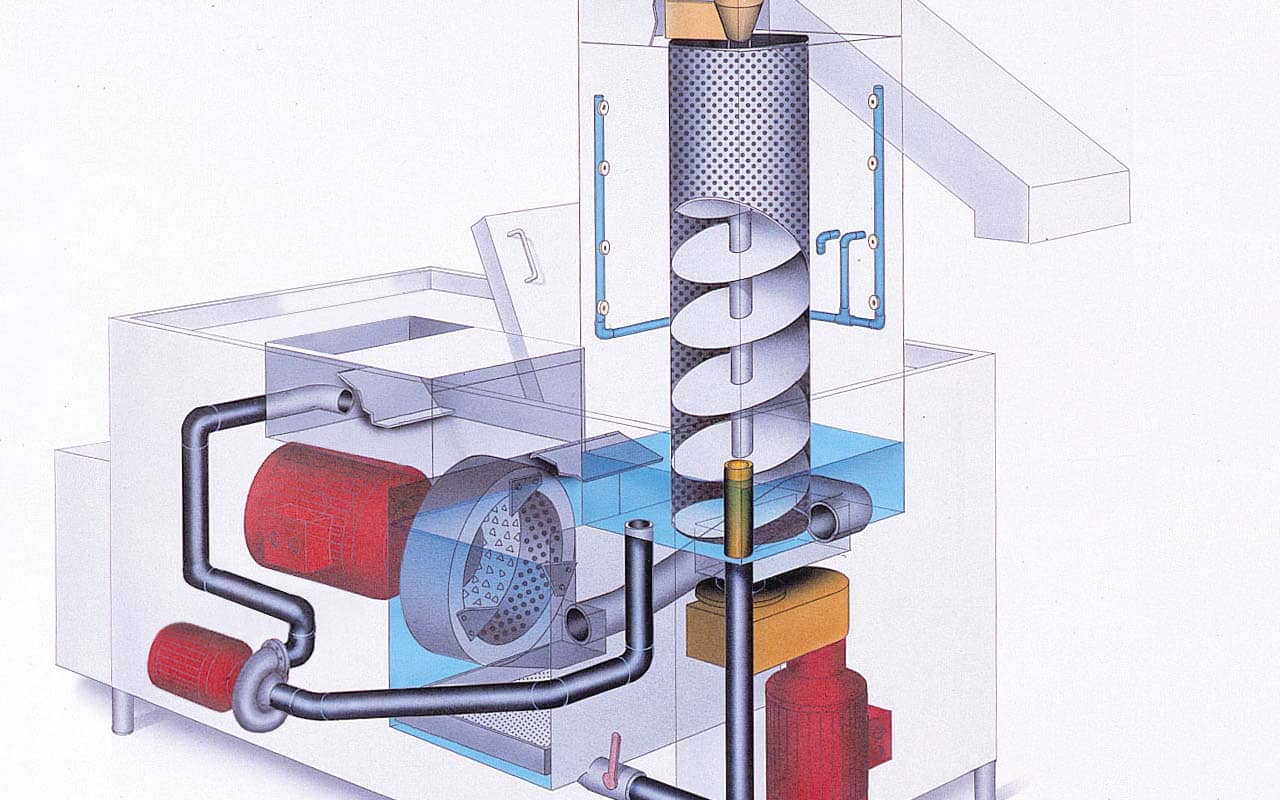

Research and development continue apace in the late 1970s and the early 1980s, with MEIKO engineers focusing on far more than just dishwashing and disinfection technology. The company develops an outstanding method of compressing and shredding food waste. Capable of tackling seafood shells, crustacean exoskeletons, and even bones, the system channels all the ground-up waste to a special collection tank. Other new developments include salad and vegetable washers and special machines for every conceivable kind of washware, including chocolate moulds, paint cups (with acid), crates and containers, circuit boards, waste bins, and much, much more.

1985

Reduce energy consumption with new technology

MEIKO sets new standards with dual rinse zones and low temperature drying systems for commercial machines. It also reduces the consumption of rinse water by 25%, and energy consumption by approx. 20%. These advances are followed by energy and chemical saving systems and – in the new generation of B-Tronic and K-Tronic machines – the first fully electronic control units with diagnostic systems and data logging.

THE 1990S

Racking up big sales

1996

Innovation: The automatic rack type dishwashing machine

Compact, powerful and highly sought-after, the K140 (now K160) automatic rack type dishwashing machine takes the market by storm and sells in its thousands, marking the latest successful innovation from MEIKO. Space is tight for many businesses, especially in the hotel and restaurant trade, and MEIKO’s new machine offers the perfect solution.

THE 2000S

Kick-starting the new century

2000

More technology

The launch of MEIKO’s new „Point2“ generation of dishwashing machines with the MIKE control system heralds a giant leap forward in human-machine communication. In German, the abbreviation MIKE stands for the first generation of a modular and integrated component-related electronic control system. It’s a big name that encompasses a whole host of powerful features! MIKE makes it easier for service technicians to inspect and check the machines. It uses an infrared interface to transfer troubleshooting and diagnostic data to a handheld device.

2004

„TopLine“ & „WasteStar“ reach the market

The TopLine range of washer-disinfectors hits the ground running and sets the bar extremely high. One of its biggest strengths is its user-friendly operation. The wash chamber keeps vapours and odours locked inside the machine, offering huge benefits to everyone who uses it. And that’s not all: MEIKO also launches its “WasteStar“ vacuum food waste disposal system that takes a hygienic approach to preparing waste for reuse. Its smaller sibling, the WasteStar CC, is launched in 2015, causing a sensation in the industry and quickly picking up numerous international awards. The food waste collected by the system can be used to generate energy, lending a hand to efforts to protect the environment.

2006

Relief for the hospitality industry

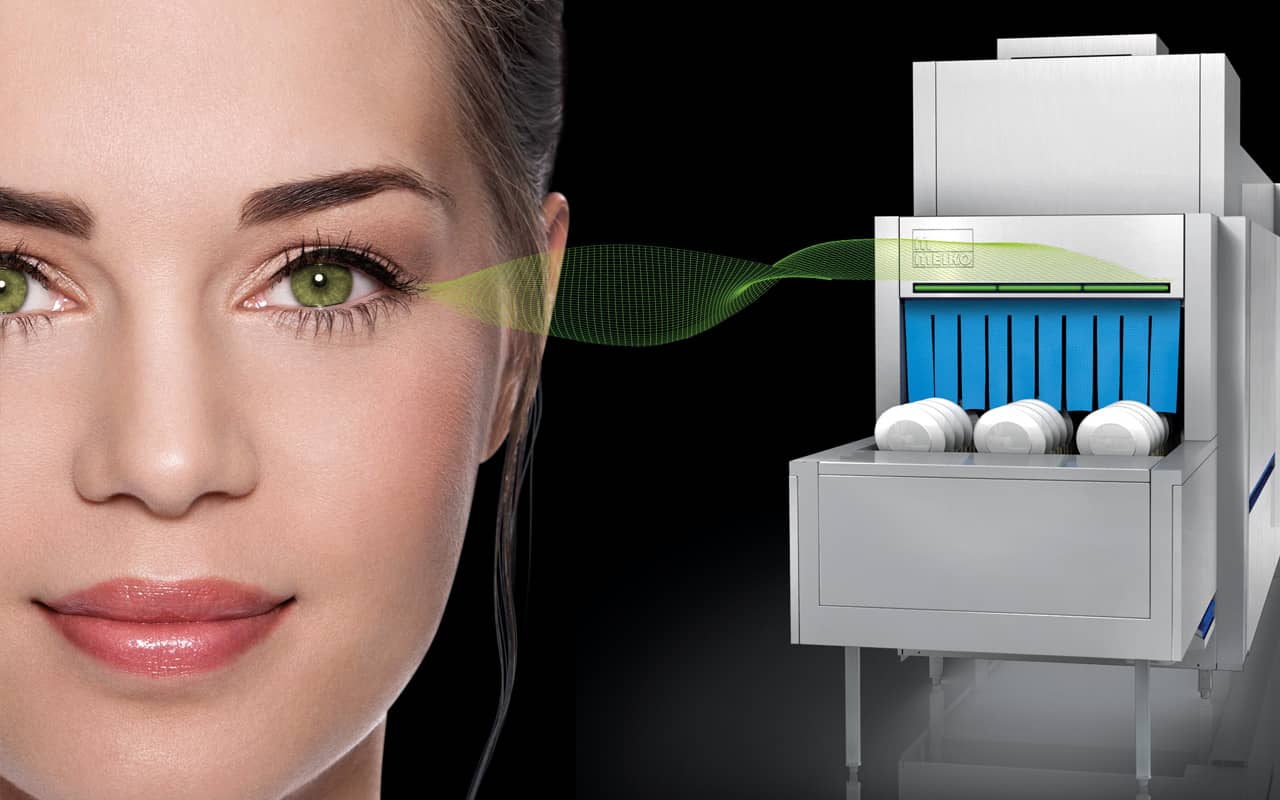

Relief and exhilaration in the hospitality industry as the message goes out that you no longer need to polish glasses by hand! MEIKO builds a reverse osmosis module for purifying water and incorporates it in a glasswasher for the very first time. It’s exactly what the market has been waiting for. Meanwhile, the M-Commander Invision analysis software for automatic conveyor dishwashing machines marks the arrival of a unique and revolutionary control system that caters specifically to commercial machines.

2009

M-iQ - An Award Winning series

The M-iQ conveyor dishwashing machine takes the market by storm with a revolutionary new design. The new range of machines is praised for its new platform concept and highly efficient and economical operation. In 2012, a new and improved version of the M-iQ is released with a built-in GiO module and GreenEye technology. The M-iQ range of machines has received numerous awards including the Baden-Württemberg Environmental Technology Prize.

2011

A new customer segment is born

MEIKO captures an entirely new segment of the market with its washer-disinfector for BA and respirator masks. Its new customers include fire departments and breathing apparatus cleaning facilities at disaster relief organisations and major industrial concerns. The TopClean M is the machine customers have always wanted. It helps them get their equipment clean quicker and with a higher standard of hygiene. The suggestion to develop this machine originally came from the Lahr Fire Service, and the MEIKO team rose to the challenge yet again, creating the perfect machine to meet their customers’ needs! Top Clean M machines are now being sold as far away as Asia.

2013

M-iClean U makes cleaning easier

M-iClean U: that’s the beauty of cleaning! MEIKO launches an outstanding range of undercounter dishwashers. Boasting an elegant design, the M-iClean U features a striking handle design that lights up in three different colours to show the machine’s current status. It also includes other selling points that dramatically improve the dishwashing experience such as heat recovery, the GiO module, and a glass display including a progress indicator.

2017

New: The hood type dishwasher

Customers flock to MEIKO’s dishwashing paradise to experience the M-iClean H hood type dishwasher – a dream machine for the dishwashing team! An automatic hood system and rack detection are two of the new features designed to create a healthier working environment. The dishwashing process has been redesigned to make it even more efficient and economical. And, just as you would expect from paradise, the machine creates a much more pleasant atmosphere to work in, with better indoor air quality. There was tremendous interest in the latest MEIKO technology at the Internorga trade fair, offering yet another reminder of MEIKO’s long history – the company has been attending trade fairs in Hamburg as an exhibitor for more than 70 years.

2018

Birth of MEIKO GREEN Waste Solutions

MEIKO and Biotrans will be moving forward hand in hand. The Swiss company is expert in the collection, treatment and storage of wet waste. Merging with them gave rise to MEIKO GREEN Waste Solutions. Commercial kitchens can now be even more hygienic, with organic kitchen waste and leftovers being used as a resource to generate energy.