ECOLOGY

Dishwasher technology with built-in sustainability

Minimal water consumption and effective energy management add up to an extremely economical washing process and top-class environmental performance. MEIKO dishwashing technology leads the way when it comes to minimising resource consumption. In the last 30 years, MEIKO technology has cut water consumption by over 70% and energy consumption by over 30%!

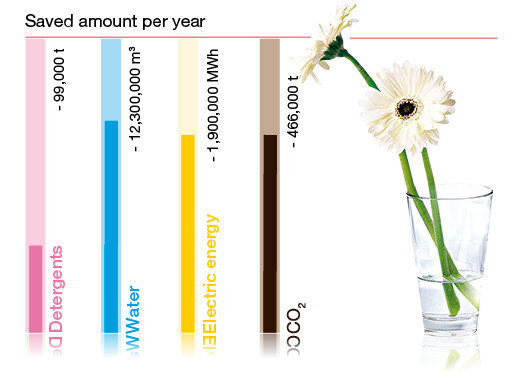

Detergents:

The annual saving potential of the M-iQ technology is approx. 99,000 tons! As these 99,000 tons of chemicals (ingredients: caustic alcalines, phosphates, disinfecting components (normally chlorine), tensides) must need not be produced in the first place, they do not constitute an environmental load (in waste water, on distribution). Savings of 99,000 tons of detergents means: 99,000 tons of detergents need not be dispatched, distributed and transported. At a barrel size of on average 500 kg this means: some 200,000 distributing runs need not be made!

Water:

The annual saving potential of the M-iQ technology is approx. 12,300,000 m³! This is enough water to supply a city of 250,000 people free of charge for an entire year.

Elecrical energy:

The annual saving potential of the M-iQ technology is approx. 1,900,000 MWh! This is enough power to supply more than 422,000 4-person households or a city of 1.7 million people free of charge for an entire year.

CO2:

At the same time, CO2 are reduced by as many as 466,000 tons!

By order of the European Commission, the Freiburg-based Öko-Institut e.V. together with the French company BIO Intelligence Service prepared a study (EuP study) which catalogues all dish washers that are in operation in the EU and i.a. lists their respective demand for resources. When using the M-iQ technology the above-quoted values would apply.

Operating cost savings and Investment:

The system offers operating cost savings in the two-digit percentage area. When an old machine (with a service life of normally 15 years) - the "greenest" machine at the time of purchase - is replaced early (e.g. after 8 years) the user saves around 20,000 €/year in operating cost. That is, the M-iQ investment is going to pay off in around 3 years.

What’s more, in the above example the emission of harmful CO2 can be reduced by as much as 150 t per machine – which is the result of direct energy savings, other potentials notwithstanding!

When an average standard machine is replaced, the savings are much higher and the pay-off times much briefer (see EuP study).