TECHNOLOGY. DESIGN. OPTIONS. SAVINGS.

Its advanced technology and smart design makes the KA Series economical, reliable and easy to use, while its efficient washing performance helps you save water and energy — no matter which size you choose. The KA Series is available in nine models — six single-tank sizes and three multi-tank sizes — so you can configure a unit to meet the exact needs of your commercial kitchen.

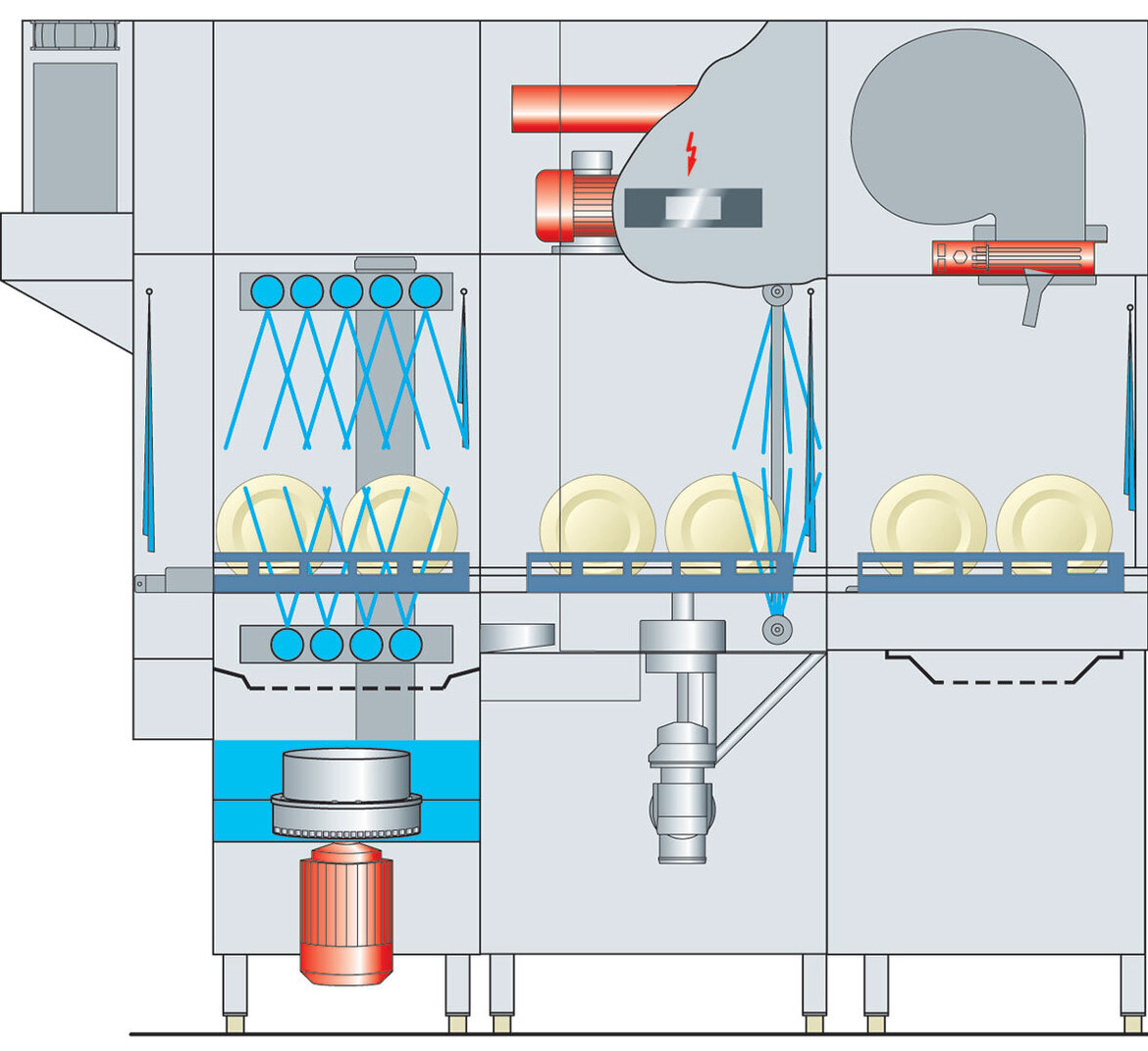

BLUE IS THE COLOR OF USER-FRIENDLY OPERATION

MEIKO’s user-friendly blue components quickly indicate which parts are suitable for hands-on cleaning. It’s fast and it’s intuitive, without bulky instruction manuals or complicated directions.

MEIKO uses a striking blue to mark all the components and parts which users can interact with – an intuitive concept which everyone can follow. No words and no long instructions necessary.

This is MEIKO's way of making communication between machines and humans as easy and efficient as possible. It's teamwork at its best – and more comfort during professional warewashing.

SAVE ENERGY AND OPTIMIZE AIR QUALITY.

MEIKO’s award-winning Waste Air Heat Recovery System (WAHRS) reclaims and reuses heat generated by the machine. Not only does this reduce energy consumption while allowing hot-water sanitization from a cold water supply, the WAHRS also helps maintain optimal indoor air quality for staff in back-of-house areas.

CONVENIENCE AND TECHNOLOGY: THE DIFFERENCE IS CLEAR.

The illuminated glass touchscreen control panel provides an ongoing overview of the wash cycle, keeping operators fully informed at every stage of the washing process. All key information is clearly available at a glance in multiple languages, reducing the risk of operator error. With simple, one-touch operation, it’s never been easier for people and equipment to work together.