PUMPED SYSTEMS

MEIKO BioMaster®

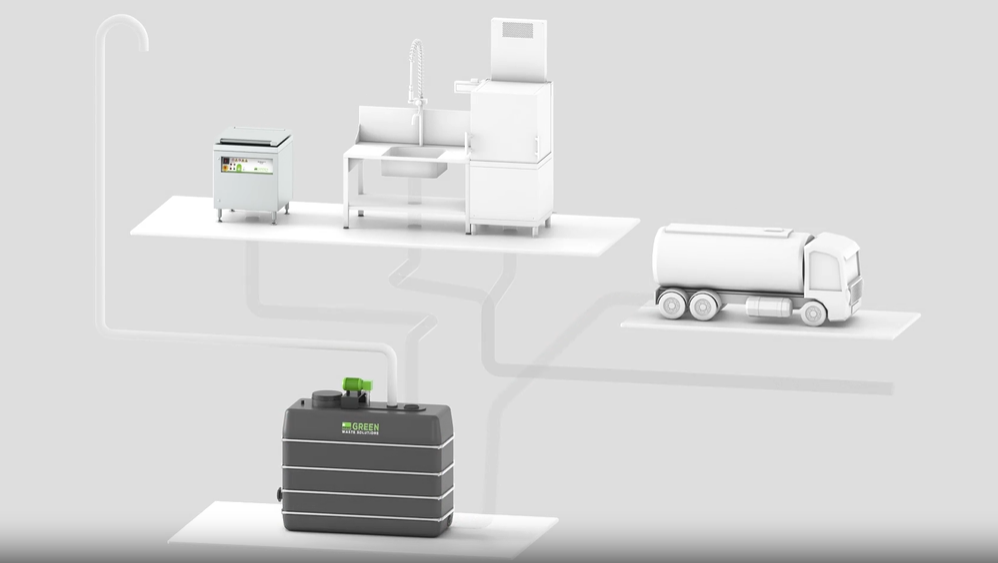

Our pumped waste systems use a process of homogenisation to convert kitchen scraps and leftovers into a liquid biomass before it even leaves the infeed station. The biomass is then pumped through a sealed system of plastic piping into a storage tank. It is then held in the tank without releasing any odours until a tanker arrives to transport it to a biogas plant. Based on tried-and-tested technology, our pumped waste systems offer a flexible and easy-to-install solution. And we've even made it easy to incorporate grease traps, so you can combine everything in one system.

VERSATILE

Economical, eco-friendly, custom made

From processing powerhouses to lean and nimble all-rounders, our BioMaster® series infeed stations are available in a wide range of formats to suit any kitchen environment. They are the core components of our pumped waste systems – and a great addition to any kitchen!

ADVANTAGES

The clever solution for leftovers and kitchen waste

Improved hygiene with less cleaning

Easy to handle

Efficient workflows

Self-contained system for safety

Longer collection intervals (fewer lorry journeys)

Synergy effects due to integration of the grease separator

Versatile tank solutions with no need for refrigeration

Minimises cutlery loss

Low disposal costs

MEIKO BioMaster® 4 HIGHLINE

High end in every way: our most efficient infeed station for all types of kitchen waste and leftovers. A standard programme and a programme for mainly dry food waste provide optimal conditions for efficient comminution and then storage of the food waste..MEIKOGREEN's innovative homogenisation technology delivers process reliability with minimal consumption of process water.. When compared to the BioMaster® 4 PLUS, the BioMaster® 4 HIGHLINE has more features to make operation even easier, such as the hand spray, the integrated water meter and an additional cleaning programme.

MEIKO BioMaster® 4 PLUS

Our BioMaster®4 Plus uses the same chassis as the BioMaster®4 Highline:150 mm ground clearance, can be plinth-mounted, easy to clean, standard-compliant water supply, attaches to tables and hygiene stations – and yet, this appliance is in a class of its own. It is the ideal choice for medium to large commercial kitchens. From breakfast to supper, all kitchen waste and leftovers are processed in just 50 seconds – of course in accordance with guidelines. In a nutshell: power, reliability and design all under one hood.

MEIKO BioMaster® FLEX

The newcomer in the BioMaster® range: The BioMaster® Flex offers the advantages of the BioMaster® range in a compact, versatile package. With a width of just 500 mm, it is extra compact and extremely flexible in terms of installation. This makes it particularly suitable for retrofitting or kitchens with limited space.

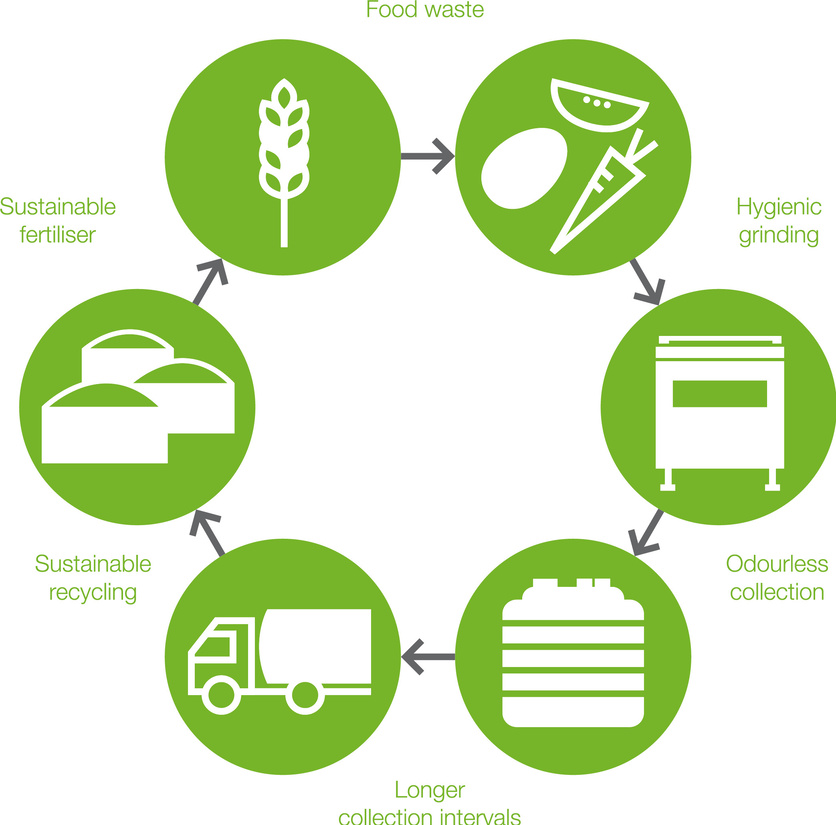

HOW IT WORKS

The right system for any needs

Our systems offer a solution to the economical and ecological questions around how to treat kitchen waste and leftovers from commercial kitchens, hotels, canteens, communal catering and more. We homogenise organic kitchen waste and leftovers, turning it into pulpy biomass and significantly reducing the volume of most organic waste. We also use the water contained in the food waste in the process, meaning very little process water is needed to keep the biomass fluid. The biomass is then channelled into the storage tank using a self-contained system and it can stay there, odour-free and room temperature for several weeks. The energy-rich resource is then collected by a suction vehicle usually every four to six weeks and taken to as biogas plant where it is converted into energy and raw materials.

STORAGE TANK

Collecting organic kitchen waste at source is crucial – and so is finding the right way to store it. The biomass produced in the infeed stations is conveyed through a sealed piping system to the storage tank, where it is held ready for collection by a tanker. This system can also be directly linked to the kitchen's grease trap, so that everything can be emptied at the same time.

Rectangular or round? Polyethylene or concrete? We find the right solution for you by considering factors such as the space you have available and the number of meals you serve. The result is a hygienic, odourless system at a safe distance from any sensitive food preparation areas. The biomass can be stored in the tank for up to six months without refrigeration. And you can breathe a sigh of relief that you no longer have to carry waste bins and containers through the building.